Canada’s new national EV Battery Recovery Program shows promise. But its voluntary, OEM-led design risks undermining the circular economy it claims to support.

Written by Ken Hendricks

Canada has taken another step into the electric future. This summer, a coalition of vehicle manufacturers, led by Canadian Vehicle Manufacturers Association (CVMA) and Global Automakers of Canada (GAC) in partnership with Call2Recycle Canada, announced the national expansion of the EV Battery Recovery Program—an initiative designed to collect and responsibly manage end-of-life batteries from electric vehicles across the country.

It’s being hailed as a landmark moment: the first national approach of its kind in North America, with promises of sustainability, circular economy benefits, and a streamlined, manufacturer-supported process to recover, repurpose, and recycle batteries that are no longer wanted or usable. For a country accelerating toward a zero-emission future, it sounds like precisely the kind of infrastructure we need.

But here’s the problem: for all its ambition, the program remains a voluntary, OEM-directed patchwork with little regulatory teeth, no binding guarantees, and minimal engagement from the people who actually handle these batteries—auto recyclers, dismantlers, and the small businesses at the forefront of managing EVs at end-of-life. In short, it is a good start, but it is far from the solution Canada needs.

The promise of the program

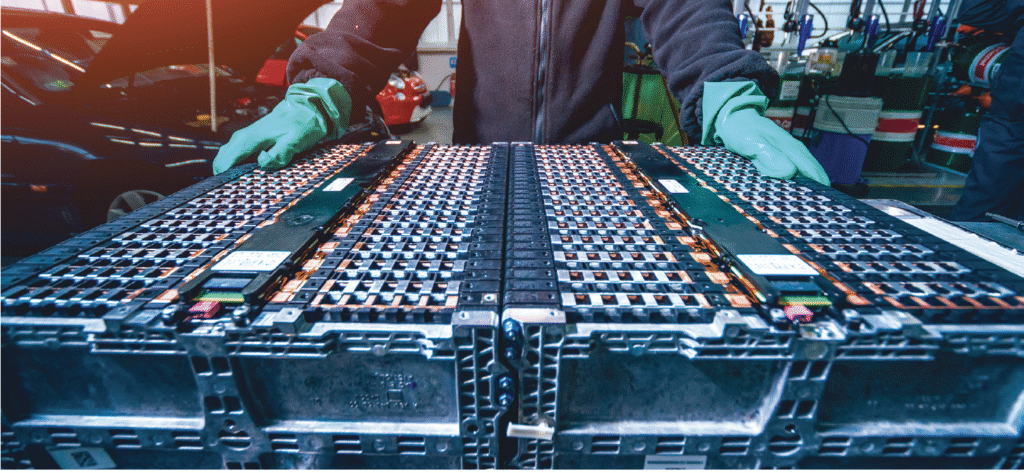

Launched originally in Quebec in 2023 as a regional pilot, the EV Battery Recovery Program has now gone national, offering recyclers, insurers, garages, and others a way to submit pickup requests for EV batteries through the EVBatteryRecovery.ca portal. The idea is to manage the growing volume of lithium-ion batteries from hybrids, plug-in hybrids, EVs, and fuel cell vehicles that fall outside traditional warranty or recall coverage. On the surface, this makes sense. End of-life batteries are heavy, hazardous, and expensive to store. Many recyclers, particularly in rural or remote areas, have struggled to responsibly dispose of “zero- or negative-value” batteries, often left stranded on their shelves for months. With the EV market poised to surge in the coming decade, solving this bottleneck is essential.

The program’s messaging is equally compelling. It supports the circular economy. It reduces environmental risk. It complements existing manufacturer-led programs. It’s a coordinated national effort that, according to industry press releases, will “reduce environmental impact,” “recover valuable materials,” and “increase dialogue” among stakeholders. What’s not to like?

Well—plenty, once you take a closer look.

A voluntary solution in a regulated world

The first issue is governance. Despite its national scope, this is not a government program, nor is it governed by a multi-stakeholder body. It is entirely OEM-led, designed and executed without meaningful industry consultation. Auto recyclers, despite being on the frontlines of battery removal, transport, and storage, were not part of the design. The same can be said for many provincial and territorial governments. There is no formal oversight mechanism, no transparent stakeholder advisory board, and critically—no mechanism for recyclers to challenge or refine how the program operates on the ground.

Second, the eligibility rules are strict— perhaps overly so. Only certain batteries are accepted. They must be unmodified. They must be removed by trained personnel, even though the facility submitting them need not be licensed, meaning a certified recycler operating safely in compliance with environmental health and safety regulations might be treated no differently than a DIY mechanic with a crowbar and a shed. This opens the door to shortcuts, inconsistent standards, and potential safety risks.

Perhaps most limiting of all: batteries that have been repaired, repurposed, or altered in any way are ineligible. The very practices that the circular economy encourages—reuse, repair, remanufacture, and extend the life of a product—are penalized under this framework. If you open a battery to diagnose and fix a fault, you void its eligibility. If you creatively reuse battery modules for secondary energy storage systems, the program washes its hands.

So much for supporting innovation and sustainability…

The risk of fragmentation

The biggest risk, however, may be fragmentation.

By making each OEM the de facto decision-maker over how and when batteries are collected, the program introduces a decentralized, potentially inconsistent model into a sector that desperately needs cohesion. Pickup schedules, eligibility criteria, and regional availability will vary by manufacturer. Already, recyclers in Atlantic Canada, Northern Ontario, and the Prairies have raised concerns that access may be slower, or entirely absent, outside urban areas. In the absence of binding service-level agreements, these concerns are valid.

Moreover, if each OEM handles batteries differently, we may soon face a confusing patchwork of overlapping recovery programs, none of which are accountable to a common standard or built to support long-term industry development. This is precisely the scenario that Extended Producer Responsibility (EPR) laws were designed to prevent.

And therein lies the crux of the issue…

A pre-emptive strike against EPR?

Let’s be honest: the national rollout of this program is not just about environmental responsibility. It’s also about political strategy. It represents a pre-emptive move by OEMs to stave off provincial or federal regulation, and specifically, the adoption of EPR mandates for EV batteries.

EPR frameworks, such as the one in place in British Columbia for other automotive products, require manufacturers to take responsibility for the full lifecycle of their products. This means developing recovery plans in consultation with stakeholders, publishing performance metrics, supporting infrastructure, and ensuring all costs—not just the convenient ones—are absorbed by the companies profiting from the sale of the goods.

Instead, what we have here is a selective, voluntary effort that allows manufacturers to control the process while avoiding the financial and operational burdens that a formal EPR system would entail. It offers the appearance of action, without the accountability.

It’s reminiscent of the CASIS agreement of 2009, another voluntary OEM initiative designed to address the issue of vehicle repair information access. While CASIS helped bridge some gaps, it never fully addressed the needs of independent repairers and left certain critical information and procedures out of scope. Similarly, this battery program creates a façade of inclusivity while reserving real control for the manufacturers.

Where this leaves the industry

So, what does all this mean for the auto recycling and service industries?

It means uncertainty. It means inconsistency. And it means that recyclers, the very people who are essential to any battery recovery strategy, are left out of the governance and unsupported in practice.

Consider this: many recyclers today are sitting on old EV batteries with no market value. They’re bulky, hazardous, and expensive to store. If the program doesn’t guarantee some form of compensation, or makes the criteria so strict that most batteries are disqualified, these batteries will continue to languish, unsafely, in yards and warehouses.

That’s not just bad for business. It’s bad for public safety and for the environment.

My take

The EV Battery Recovery Program is not a bad idea. In fact, it’s a necessary one. We need a national framework to handle the coming wave of end-of-life EV batteries, and OEMs should be part of that solution.

But the current program is insufficient. It is not designed to maximize value for consumers or recyclers. It does not support the full spectrum of the circular economy. It lacks accountability. And worst of all, it risks becoming a smokescreen for inaction, distracting regulators and the public while critical infrastructure fails to develop.

If Canada is serious about a sustainable electric vehicle future, we need to go further. We need regulations that ensure all batteries—not just a curated few—are responsibly managed. We need support for emerging reuse and repair markets. We need clear, enforceable standards across provinces. And we need to involve the people doing the work, not just the ones writing the press releases.

Innovation is crucial. But so is equity. A truly circular EV economy must work for everyone, not only for those who can afford a new vehicle every few years. That means building a system that supports longevity, affordability, and safety, not just for batteries, but for the broader ecosystem around them.

Until we get there, this program remains what it is: a step forward, yes—but a cautious, limited one, with too many strings left untied.